|

|

Tungsten AM parts | |

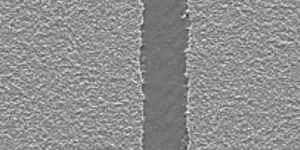

Stents cutting |

Plasma in the air |

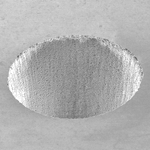

Hole drilling in glass |

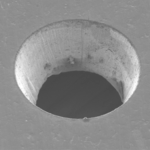

Hole drilling in steel |

Plastic blackening |

Steel blackening |

Flexible plastic solar cell scribing |

|

2D grating on glass |

|

Additive Manufacturing (AM) Machine (Tungsten LAM) is a breakthrough technology developed in PolarOnyx to

- manipulate microstructures

- create high melting temperature (over 4000 oC)

- control small feature size

- melt any type of materials (metals, ceramics, etc.)

- multi-material synthesis

- integrate SM to make hybrid process (AM+SM) using one fs fiber laser

Our laser processing (SM) system (Femto-Writer) adopts the most advanced high energy fs fiber laser (from UV to mid-Infrared) for micro-and nano-structuirng of materials, such as metals, glasses, polymers, semiconductors, and ceramics. It can perform a variety of functions such as cutting, ablating, drilling, welding, marking, blackening, coloring, engraving, etc. The unique features are:

- Sub-micron resolution

- Super blackening surface

- Heat affected zone (HAZ) free processing

- High throughput process with MHz

- High performance/cost ratio

Customer can have options to either work with us to develop process and own the equipment, or have us provide a one-stop service (contract manufacturing).

If you need to discuss your specific application, please email us at sale@polaronyx.com.

Researcher Friendly Table-Top AM and SM Systems

To meet R&D customers' need, PolarOnyx has developed tabletop AM and SM systems that have complete functions of the integrated machines at affordable cost. The tabletop version provides university and industrial researchers full access to the machine and make change for both hardware and software. This is the best learning and researching tools for R&D scientists and engineers.

If you need to discuss your specific needs, please email us at sale@polaronyx.com.